1 Vacuum Pumps: Which Is Best For Refrigeration Applications?

When it comes to selecting the correct vacuum pump for your application there are a number of factors that need to be considered:

- Application of use: small or large systems

- Frequency of use: daily or monthly

- Speed required: long evacuation or fast

- Ultimate vacuum required: e.g. a deep vacuum is better for dehydration

- Quality: is the pump to be used once or a few times?

- The Price—of course, everyone has a budget, but poor tools = poor results.

Pump Abilities

Small portable applications such as domestic refrigerators and freezers can easily be evacuated using a smaller vacuum pump where the speed is not so critical. A vacuum pump with a 30–80 litre/min range is thus adequate. However, it must be a 2-Stage pump or have the ability to achieve a deep deep vacuum.

For larger applications the 150 litre/min or 6CFM is ideal—it’s fast yet still portable enough for easy use. Again it must be a 2-Stage pump or have the ability to achieve a deep vacuum.

When it comes to even larger commercial systems or chillers, bigger is better. The most desirable is a 2-Stage pump producing 300–500 litre/min or more.

However, be warned : using a pump with hose or inlet lines any smaller than the suction fitting opening on the pump will result in significant losses. Pump manufacturers design the optimum inlet for their pumps. So using a 1/4" line on a 300+ litre pump is a hindrance to its capability. The minimum is 3/8" but 1/2" or 3/4" will see significantly faster evacuations.

Now, don’t attempt to use one pump for several evacuations at the same time. It is possible, though the weakest or leakiest system will govern the vacuum strength in the group—meaning multiple evacuations at the same time can actually take much longer in practice. Most refrigeration production lines use one individual pump per refrigerator—yes, hundreds of pumps per line … they know the rules.

It is also important that you consider the type of pump protection required. A pump located in a hazardous area may possibly cause an explosion if the motor is not of the correct protection class. If you are not aware of this, then it’s vital you seek professional advise.

Expert Advice For The Best Pump

As you can see, there are a number of variations and performance elements that need to be taken into account when selecting a vacuum pump. If you are unsure about what is available or need assistance, then please contact HVAC Direct on 03 9765 2799 or fill out the contact form here. We will ensure you get the most efficient pump for your needs.

2 Experiencing Poor Vacuum?

Ultimate vacuum takes time—real time = a quality evacuation. The optimum vacuum is relative to pump capacity, quality, oil and system size and integrity. Perpetual pump maintenance is vital to optimum vacuum as well.

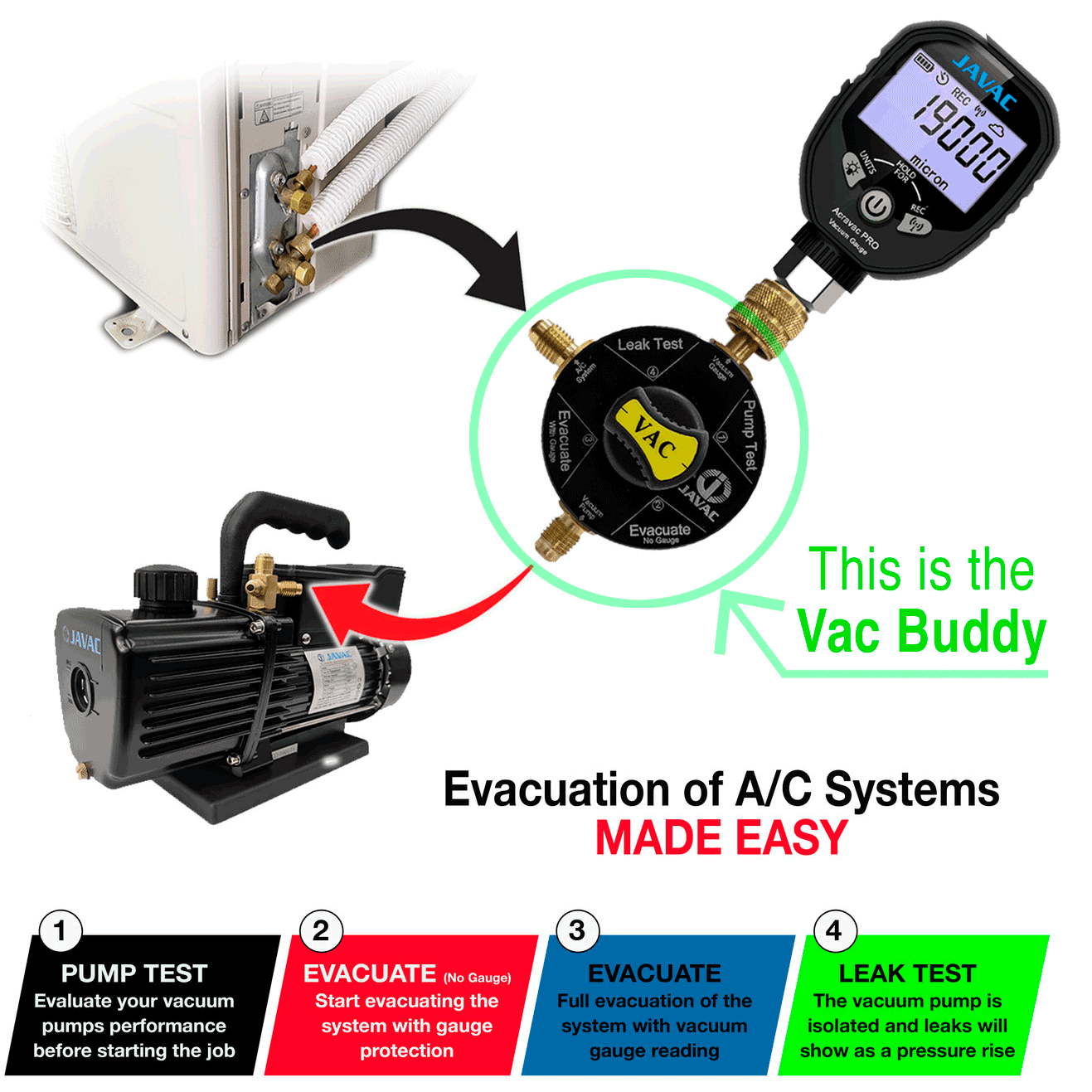

If it appears the rotary pump is not achieving high vacuum, check these:

- How good is your gauge?

- Is the oil level correct when pumping.

- Are all hoses tightly fitted and valves shut?

- When was it last serviced? Like a high-end car, vacuum pumps need regular servicing.

A Possible Solution

If no improvement is achieved, check the unit with a quality McLeod reference gauge or electronic gauge and follow these instructions:

- Remove pump from system.

- Connect the gauge to suction fitting … ensure it’s sealed properly.

- Ensure all other connections are secure.

- Run the pump. A McLeod gauge should indicate a vacuum of between 50 and 1 micron. An electronic gauge will show approximately 250 to 20 micron after five minutes, depending on the type of pump. The vacuum should be steady.

- If the vacuum is poor, drain the pump and refill with fresh manufacturer’s high grade vacuum pump oil ONLY. Do not use any other oil made for other manufacturers.

- Run again. If the pump is good but the vacuum is poor, the problem is elsewhere. The pump probably needs a service.

3 Why Your Pump Needs Genuine Manufacturer’s Vacuum Pump Oil

It is extremely important to use the correct viscosity oil, as those that are either too thin or too thick will cause serious damage and operational issues to your pump.

It is vital that you do not use refrigeration compressor oil as it is not designed for vacuum pumps. It will cause serious damage … so don’t ever use it.

Contamination Problems.

The oil MUST be changed when contaminated. Contamination is usually indicated by poor vacuum reading, or a grey or milky appearance.

Should liquids be accidentally allowed into the pump, CHANGE THE OIL IMMEDIATELY. Your high vacuum pump is a precision instrument and a change of oil is less expensive than a pump service and repairs.

If changing the oil hasn’t helped, then your pump should be serviced.

Recommendation

We take pride in every Vacuum Pump we supply and ensure you of our long-term interest in our product’s reliability. For your continued satisfaction, HVAC Direct highly recommends OE oils.

4 Still Can’t Achieve A Good Vacuum?

If a decent vacuum cannot be reached there may be problems with a larger number of joints, or possible leaky points. This can be checked and a solution found using a tracer gas, an ultrasonic leak detector or, in the case of automotive systems, a tracer fluid within the oil.

5 Why Use A Vacuum Pump?

If you don’t know you really shouldn’t be doing this. But for the uninitiated, any moisture that forms in a refrigeration circuit has the potential to freeze and create blockages, corrosion and, therefore, inefficiency.

The vacuum process doesn’t just remove the air. It dries the system by reaching a pressure that allows the moisture and oil to evaporate out of the circuit thus creating a dry environment whereby the HVAC system can achieve its maximum efficiency.

‘Dehydration’ is the correct term for this process and it takes time as just 1 gram or 1 cc of moisture creates up to 1 m3 of moisture vapour that the pump must remove. The pump needs to be super hot to remove all. If it doesn’t, it will show as milky oil in the pump and this milky appearance is evident that residue moisture is still present, the result of which will reduce vacuum and cause corrosion.

If the vacuum pump has a gas ballast, USE it. It's designed to remove water vapour from the oil.

Weather-wise, at cold temperatures the process takes longer … on hot days, evaporation is fairly quick.

6 How Long Should I Pump Down For?

Good question. It is not a matter of time but really the vacuum you achieve and maintain. That’s why professionals use a quality vacuum gauge and don’t just guess.